{include file=head2.html}

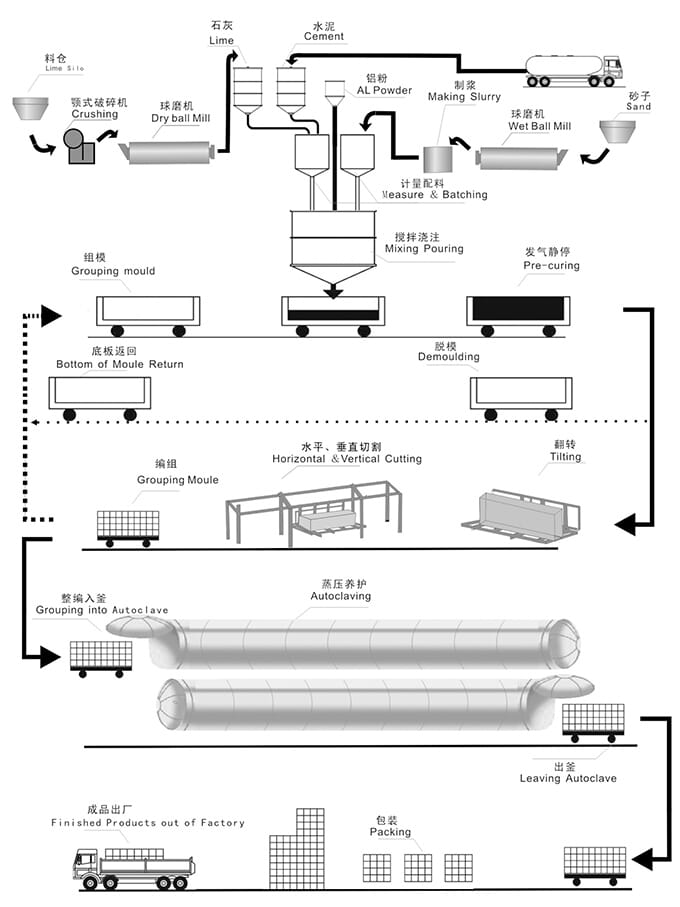

Feature: Capacity: 60s online 2 days customize Factory Deliver the goods Professional Free 365 days Project tracking 2 days provide Pre-sale service Sales service After-sales service Tip1: The specific time arrangement depends on the actual situation. Tip2: Free airport transfer and hotel accommodation. We have total series of AAC Block making line from 20,000-600,000m³/year. Welcome contactl us customize your business now! Autoclaved aerated concrete is a high-quality building material made of quartz sand, quicklime, cement, aluminum paste, and water, and various natural chemical reactions occur during the manufacturing process, which are the high-strength, light-weight properties of air-entrained concrete. quality and thermal properties. FTL Machinery (also known as Yigong Machinery) are the professional AAC block plant manufacturer in China, we have 40+ years’ experience of manufacturing and design in AAC block production line. AAC block plant is specialized for autoclave aerate concrete blocks producing. The density of aac block can be 350-700kg/m³. All the parts and design adopt German technology. The main parts include Raw material preparation, dosing, mixing, pouring, pre-curing, cutting and autoclaving. 600,000 m³ per year AAC block plant is a fully automatic type plant. Any problem from the aac production line can be detected timely. The production line including raw material preparation, dosing, mixing, pouring, pre-curing, cutting, autoclaving and packing. We are located in Zhenzhou city, Henan province, China, starting from 1978. We have sold more than 100 sets of AAC plants to Domestic market, Italy, Ukraine, Russia, Mongolia, Uzbekistan, Kazakhstan, Iran, Chile, Indonesia, etc. All of them run successfully. Always use famous brand spare parts for production; Always final Inspection before shipment; Founded in 1978; 50000 square meters; 12 workshops; More than 200 employees More than 100 sets of processing equipment for casting, forging, thermal treatment, welding, assembly, cutting, etc. Accepted Delivery Terms: FOB,CFR,CIF; Accepted Payment Currency:USD,EUR; Accepted Payment Type: T/T,L/C; Language Spoken:English,Chinese,German,Russian 1. The raw materials (quicklime, cement and gypsum) are stored in the storage silos and fed to the mixer in a controlled process. 2. The sand is prepared with a certain quantity of water in the ball mill for wet grinding to form a sand sludge. 3. The precisely weighed raw materials are fed in a specified sequence to the pouring mixer. Here a homogeneous mass is produced exactly according to the recipe specifications that are set and processed by a control system. 4. The aerated concrete mixture is poured from the mixer into an oiled mould. After that, the filled moulds are transferred to the resting and pre-curing room , under a certain temperature and time, the green body will reach a certain hardness for cutting. 5. As soon as the cutting characteristics of the green body are achieved, the mould is forwarded to the demoulding area. Here the body is gently separated from the mould. The empty mould can be oiled either manually or in a completely automated way before it is prepared for re-filling under the mixer. 6. Before cutting, the AAC body is tilted by 90°. Standing upright, the body goes through the individual stations of the cutting line (vertical cutter, horizontal cutter). We can provide various cutting machine to suit your production capacity levels. 7. The body is set on the steam-curing cart by unfinished product hoister, then grouping the cut blocks and sending the into autoclave. 8. The autoclaving is carried out in long pressure vessels (autoclaves). The autoclaving process is carried out according to precisely defined procedures. The usual duration is between 10 and 12 hours. During autoclaving, the aerated concrete acquires its final quality properties. 9. The finished AAC blocks are packed in the packing line either manually or in a completely automated way. 10. The bottom (side) plate and cart return back. From 15,000m³ per year-600,000m³ per year. Of course, you can come China or to Uzbekistan, where we have our agent there. We use famous brand spare parts for our AAC plant, such as Siemens electrical motor, Luoyang bearing, Wannan motor, etc. And we provide 36 months warranty for our AAC plant. Yes, even the cutting machine, autoclave, and boiler can be put into container. Sure, we have many engineers at abroad right now, such as Uzbekistan, Kazakhstan, Africa, etc.

AAC Block Plant Series

Warranty: Three Year

Payments: L/C,D/A,D/P,T/T,Western Union,MoneyGram,negotiable payments

After-sales Service Provided: Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Long service life

20000-600000m³/y

customer service

solutions

visiting anytime

in batches

field installation

field training

after-sales online

regularly

maintenance planAAC Block Plant Series

20,000-50,000m³/year AAC block plant(Read More)

50,000-100,000m³/year AAC block plant(Read More)

100,000-300,000m³/ year AAC block plant(Read More)

600,000m³/year AAC block plant(Read More)

Why Choose Us

1. Who are we?

2. How can we guarantee quality?

3. Why should you buy from us not from other suppliers?

4. What services can we provide?

AAC Productio Process

AAC Production Line Description

FAQ of AAC Production Line

1. Which capacity do you have?

2. Do you have running worksite to visit?

3. How about the warranty?

4. Can we put all machines in container?

5. Can you send engineer to do installation?

{include file=form.html}

FTL Machinery (YIGONG)-Mining Machine Manufacturing and Exporting Base Based on the high quality and complete after-sales service, our products have been exported to more than 80 countries and regions. FTL Machinery has been the choice of more than 100,000 customers. Provide 7 * 24 hours after-sales The overseas service team can Promise leatest one-year guarantee

consultation service

arrive at the site within a week

period and free maintenance

{include file=foot.html} {include file=side.html}