Cement Production Line Description

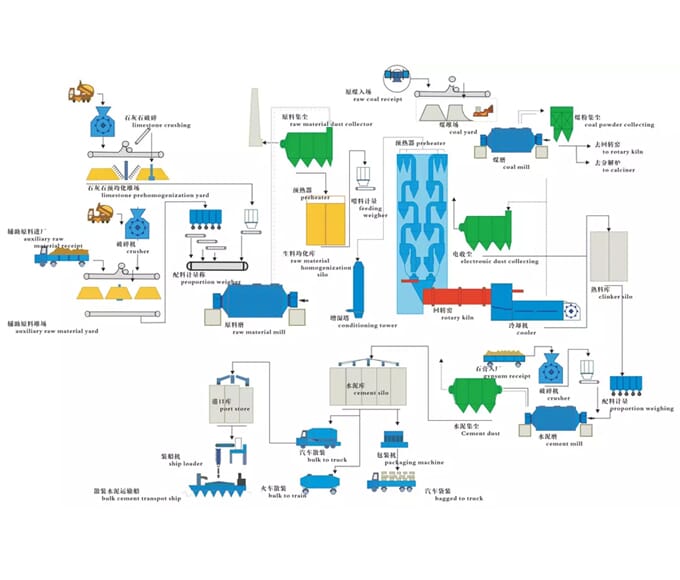

The cement making machinery (cement plant) is a cement equipment production line composed by a series of equipment. This production line mainly consists of the process of crushing and prehomogenization, raw materials homogenizing, preheating decomposition, cement clinker firing, cement grinding & packaging.

The main equipments used in this whole production line include the vibrating feeder, jaw crusher, impact crusher, cement ball mill lifer, preheating system, cement rotary kiln and packing machine and so on. All the cement equipment in this line can be provided by our factory.

We offer Cement Plants (Capacity varying from: 100 TPD to 5000 TPD ) on turn key basis and have capabilities to undertake all aspects of the project from :- Raw Material Analysis ---Project site Inspection ---- Designing Plants based on Individual requirement ---- Civil Foundation Work ---- Erection and Commissioning of the Plant and Machinery ---Training of the Staff

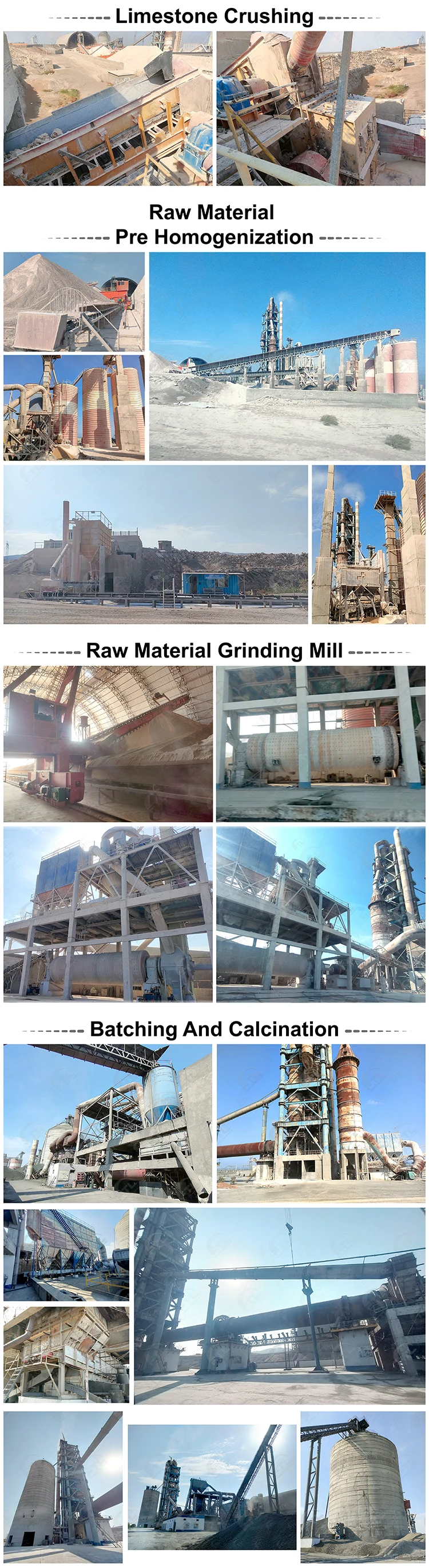

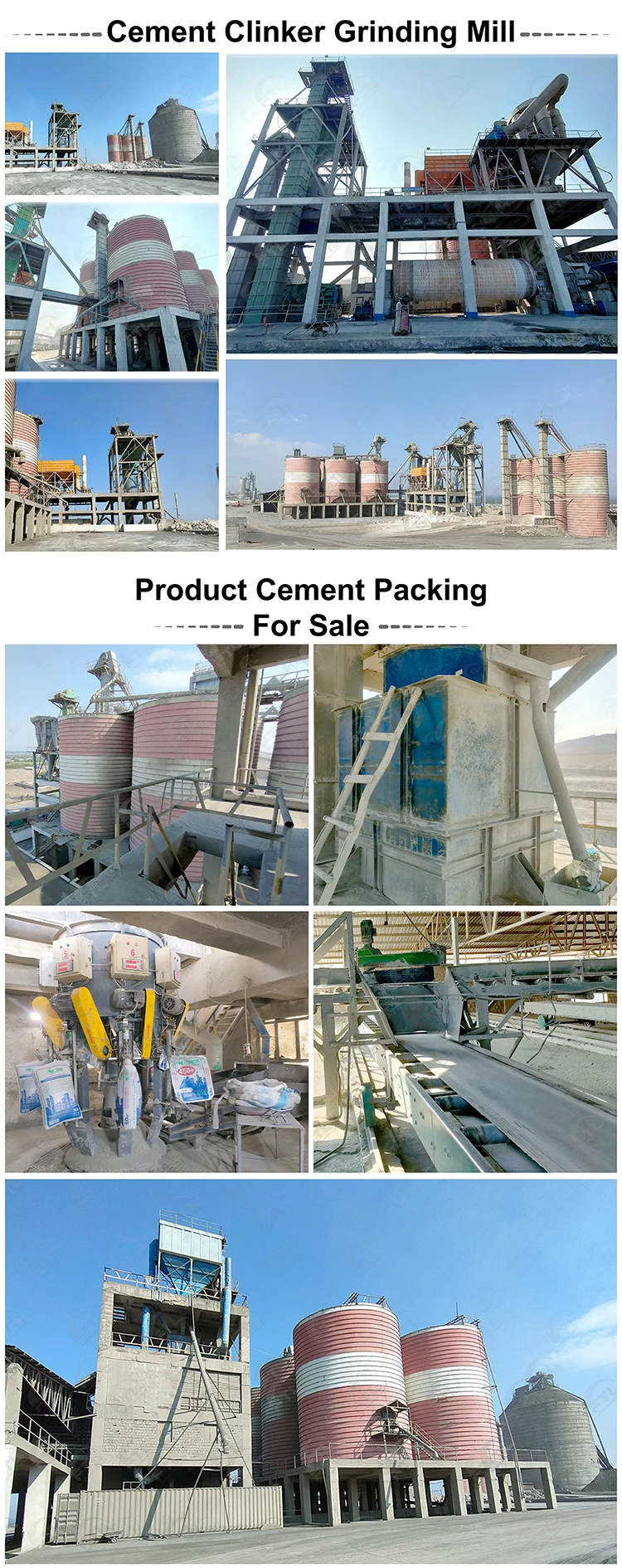

Successful Running Worksite of Our Cement Line Projects

FAQ of Cement making line

1. Which capacity do you have?

From 100TPD-5000TPD

2. Do you have running worksite to visit?

Sure, we have successful running worksite from 300TPD-2500TPD in Uzbekistan. And we even got their government award.

3. How can I start a cement production line?

It depends. Will you start from limestone quarry or cement clinker? If limestone quarry, you need start with your limestone analysis report and relevant permission certificate. If you start from cement clinker, it is better to find cement clinker supplier nearby to save transportation cost.

4. Service and Payment Terms?

A. We usually accept T/T, L/C, but other terms also workable.

B. We take pictures of finished products before delivery.

5. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round tickets, accommodation, and food

Why Choose Us

1:More than 40 years' experience

2:Have successful runnning worksite

3:Excellent installation team and installation service for you; Provide you with operating and training services;

4:Help with the equipment commissioning and solve problems in trial operation;

5:Check before acceptance of single equipment or whole production line;

6:Service items including follow-up visit, customer satisfaction surveys and so on;

7:Timely provide you with necessary accessories after acceptance;

8:Provide you with warranty services of repair, replacement and refund if conditions are fulfilled.

9:Help you solve other problems.