Stone Crushing Line Description

FTL Company offers both Stationary and Mobile Crushing Plants, adaptable to your specific project needs.

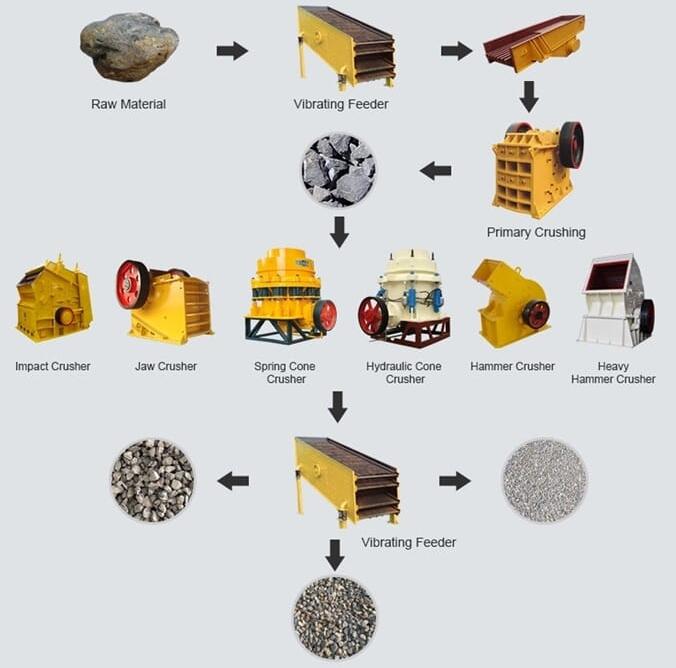

All our crushing systems follow this proven, high-efficiency workflow: The material is consistently fed by the feeder into the primary crusher (coarse crusher) for preliminary crushing. The resulting coarse material is then conveyed by the belt conveyor to the secondary crusher (impact crusher) for further processing. Finally, the material is accurately classified by the vibrating screen. Crucially, any stones that do not meet the required particle size are automatically returned to the secondary crusher for re-crushing, ensuring a high-efficiency closed-circuit process that maximizes yield and guarantees final product specifications.

Stationary Crushing Plants: Ideal for long-term, high-capacity operations where stability and massive throughput are required.

Mobile Crushing Plants: Perfect for projects requiring site-to-site flexibility, frequent relocation, or operation in remote/dispersed areas, offering quick deployment and reduced logistics costs.

FTL Company is committed to providing the most suitable and efficient crushing and screening solution for your project.

Stone Crushing Process

Detailed Images of Stone Crushing Plant Equipment

Running Worksite of Stone Crushing Line

FAQ of Stone crushing line

1. How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every crusher before delivery. And we use Siemens electrical components to make sure long service life of the power control cabinet.

2. Guaranteed service?

During warranty period, we will be responsible for all damages, including wearing parts, human damage, etc.

3. Are you factory or trading company?

We are factory. And we have drawings for each machine. After signing contract, we can send all machine drawings for free.