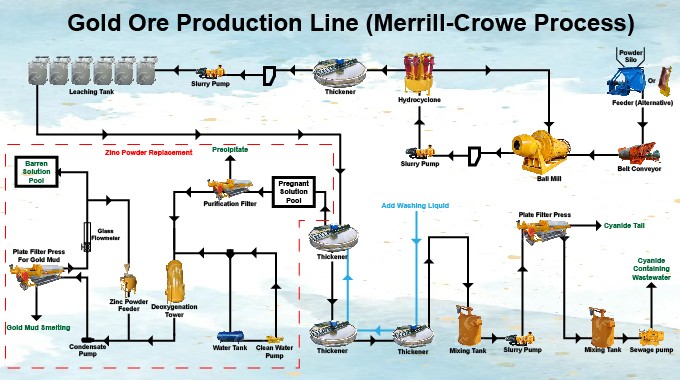

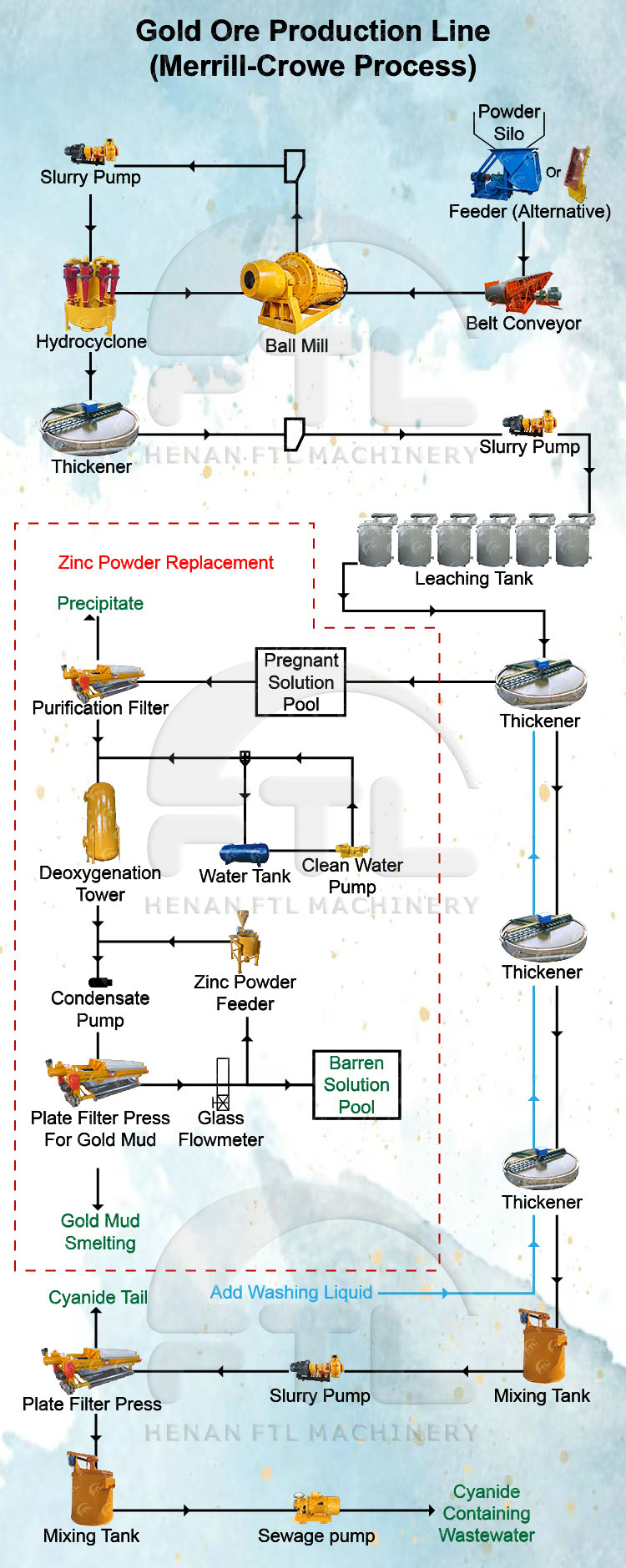

Gold cyanidation Merrill-Crowe zinc powder replacement gold extraction process

Introduction of cyanidation-Merrill Crowe gold extraction process

The zinc powder replacement process for gold primarily consists of several stages: pretreatment, zinc powder addition, replacement reaction, and gold slime treatment.

1.Pretreatment: Also known as the preparation of gold-bearing solutions, this involves subjecting gold-bearing ore to a series of mineral processing steps—such as crushing, grinding, flotation, or cyanide leaching—to obtain gold-bearing solutions. The resulting solution undergoes necessary pretreatment, including pH adjustment and removal of impurity ions, to ensure the subsequent replacement reaction proceeds smoothly.

2.Zinc Powder Addition: The amount of zinc powder is determined based on the gold content in the solution and other conditions. It is then uniformly added to the gold-bearing solution. Methods such as mechanical stirring or air agitation can be employed to ensure thorough contact between the zinc powder and the solution.

3.Displacement Reaction: Under suitable conditions of temperature, agitation intensity, and reaction time, zinc rapidly undergoes a displacement reaction with gold ions upon contact with the gold-bearing solution, forming metallic gold precipitate and zinc ions. Chemical parameters such as pH and redox potential must be closely monitored throughout the reaction to ensure efficient progression.

Main equipment

The main equipment used in the cyanide-zinc powder replacement gold extraction process includes thickener, leaching tank, deoxidation tower, zinc powder adding device, filter press, dosing machine, gold mud smelting equipment, etc.