Copper Ore Beneficiation and Gold Ore Mining Equipment

In modern mining, copper and gold beneficiation technologies are crucial, as they directly affect mineral extraction efficiency, product quality and resource utilization. We provide comprehensive copper and gold ore beneficiation equipment and technical solutions to help customers maximize benefits in the process of resource mining.

Copper Ore Mining

Copper ore beneficiation is the process of extracting copper from ore, which usually includes multiple sections such as crushing, grinding, flotation, concentration and refining. Through advanced beneficiation technology, our equipment can effectively extract various types of copper ores such as oxidized copper ore and sulfide copper ore. Our solutions include: Ore Floatation process, Gravity and magnetic separation technology, copper ore leaching process, etc.

The copper ore flotation process includes the following stages:

1. Crushing and grinding: The copper ore is sent to the crusher and grinding equipment to be processed into small particles. This step can increase the specific surface area of the copper ore, which helps to expose the copper minerals to the subsequent flotation.

2. Mixing and slurry preparation: In the agitation equipment, the finely ground ore is mixed with water, reagents and frothers. Reagents such as collectors, modifiers and activators are added to enhance the attachment of the desired copper minerals to the bubbles.

3. Froth flotation: Air bubbles are introduced into the flotation cell to form a foam layer on the surface. The hydrophobic copper minerals adhere to the bubbles and rise to the top of the flotation cell to form foam, while the hydrophilic gangue minerals remain in the slurry.

4. Concentration: The foam containing copper minerals is skimmed from the top of the flotation cell and collected as concentrate. The concentrate usually contains a higher proportion of copper and will be further processed for smelting or refining.

5. Tailings treatment: The remaining slurry, called tailings, contains gangue minerals and is discharged from the flotation cell. Proper tailings disposal is a necessary measure to reduce environmental impact.

The success of the flotation process depends on various factors, including the mineralogy of the ore, particle size, pH, temperature, and the selection and dosage of reagents. Depending on the specific requirements of the operation, different types of flotation cells may be used, such as mechanical flotation cells or flotation columns. Overall, the flotation process is widely used in the beneficiation of copper ores and plays a key role in the copper mining industry to extract valuable copper minerals from complex deposits.

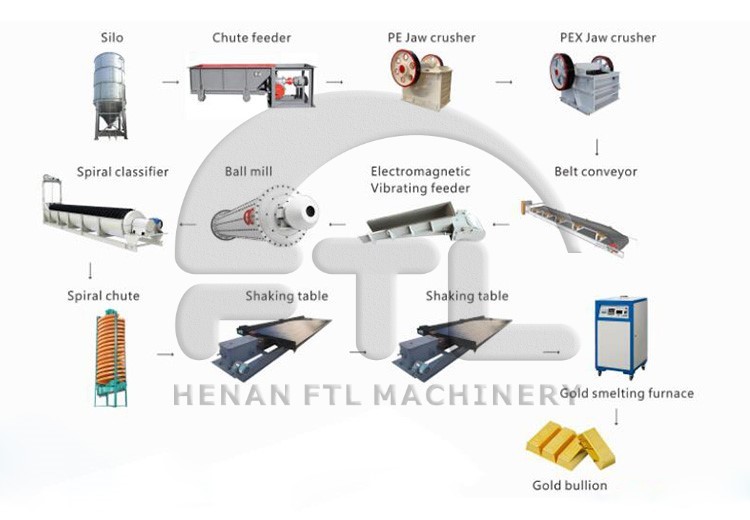

Gold ore mining

Gold ore beneficiation usually uses a variety of technologies such as cyanidation, gravity separation, flotation, etc. to extract metals from gold ore. According to the characteristics of the ore and the mining environment of the gold mine, we provide customers with tailor-made beneficiation solutions to achieve higher recovery rates and lower production costs. Our gold ore beneficiation technologies include: Cyanide Leaching, Gravity separation and Flotation separation

Cyanide leaching: Use cyanide solution to dissolve gold from the ore, and extract high-purity gold through processes such as carbon slurry adsorption and roasting, such as gold CIP process, gold CIL process and Merrill-Crowe processing methods.

Gravity separation: For raw ores with a high gold content, gravity separation technology is used to effectively remove impurities and improve gold recovery.

Flotation: Especially suitable for polymetallic ores containing gold, flotation separation is used to improve the extraction efficiency of gold.

Gold Ore Processing Equipment stock in factory

FAQ of Ore Mining equipment

1. How to choose suitable ore beneficiation machines?

To choose the right ore mining equipment, first you need consider the ore type and properties. It will be very helpful if you can send the raw ore analysis report.

2. Do you have running worksite to visit?

Sure, we have successful running worksite in China. You are highly welcomed to come and visit our client's running worksite.

3. Service and Payment Terms?

A. We usually accept T/T, L/C, but other terms also workable.

B. We take pictures of finished products before delivery.

4. Will you help with installation and staff training?

Yes, we can send our engineers to your place to guide the installation and train your workers if needed, but the buyer should bear our technician’s round-trip tickets, accommodation, and food, etc.