Gold cyanidation Merrill-Crowe zinc powder replacement gold extraction process

Introduction of cyanidation-Merrill Crowe gold extraction process

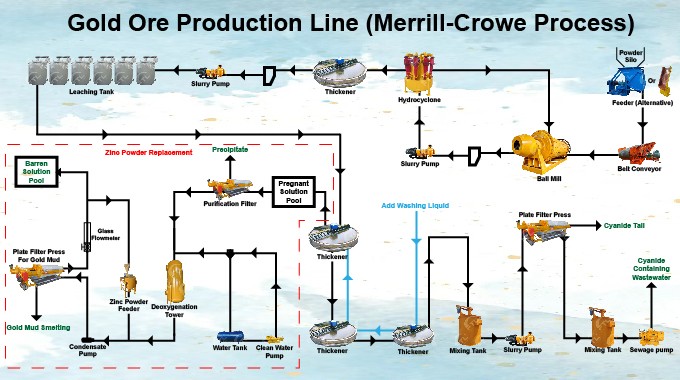

The cyanidation-Merrill Crowe zinc powder replacement gold extraction process mainly includes chemical addition and aeration, stirring leaching, countercurrent washing, zinc powder replacement, gold mud smelting, tailings filter pressing, sewage treatment and other stages.

1. Stirring leaching---The leaching of gold is mainly realized in the leaching tank. The cyanide-containing slurry is strongly stirred under the action of the impeller and compressed air, which is conducive to improving the leaching effect. The leaching tank usually adopts multiple series configurations;

2. Countercurrent washing---It is a process commonly used in cyanidation plants, usually in the form of multiple single-layer or multi-layer thickeners. The function of countercurrent washing is to use the upper clear water of the next thickener to feed the previous thickener to "dilute" the slurry, so that the liquid phase gold content gradually decreases until it reaches the established standard. Countercurrent washing is the process of "dilution" and concentration of the slurry. Some cyanidation plants also add filter pressing operations before washing, and the filter cake is added with washing water to adjust the slurry before washing. Usually, the supernatant of the first thickener is used as the pregnant liquid for zinc powder replacement operation.

3. Zinc powder replacement---is the process of adding metal reducing agent (zinc powder) to cyanide precious liquid to precipitate gold and silver into gold mud through chemical reaction, which usually includes the stages of deoxidation of pregnant liquid, addition of zinc powder and lead acetate, and filter pressing to produce gold mud.

Main equipment

The main equipment used in the cyanide-zinc powder replacement gold extraction process includes thickener, leaching tank, deoxidation tower, zinc powder adding device, filter press, dosing machine, gold mud smelting equipment, etc.