1. what is ALC panel?

ALC (Autoclaved Lightweight Concrete), with silica sand, cement, aluminum and lime as the main raw materials, has a two-way steel mesh with anti-rust and anti-corrosion treatment, and is an excellent new building material by high temperature, high pressure steam, forming porous concrete panel.

Panels can be divided into wall panels, exterior wall panels, roof panels and floor panels according to their uses. The reinforcement of each panel is based on design load, material thickness, length, etc. The thickness is usually supplied from 50mm~300mm, the interval is 25mm, and the maximum length is 6m (>=150mm thick).

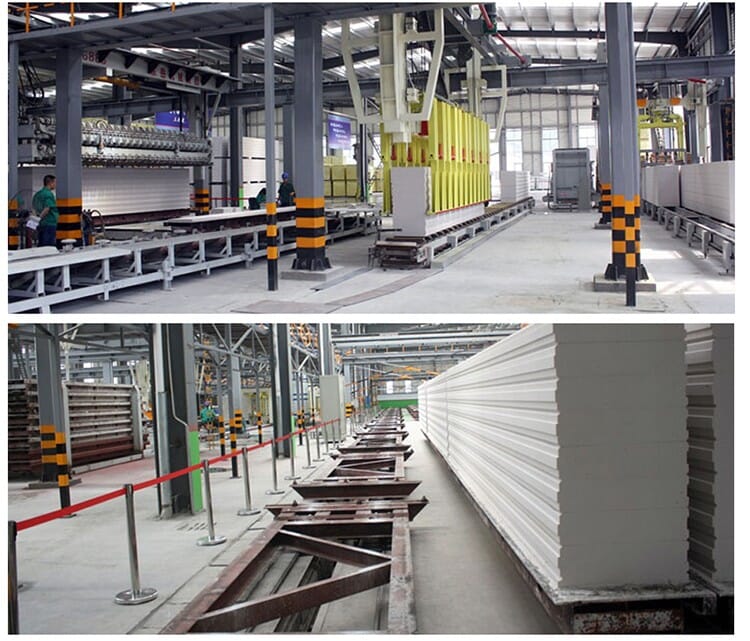

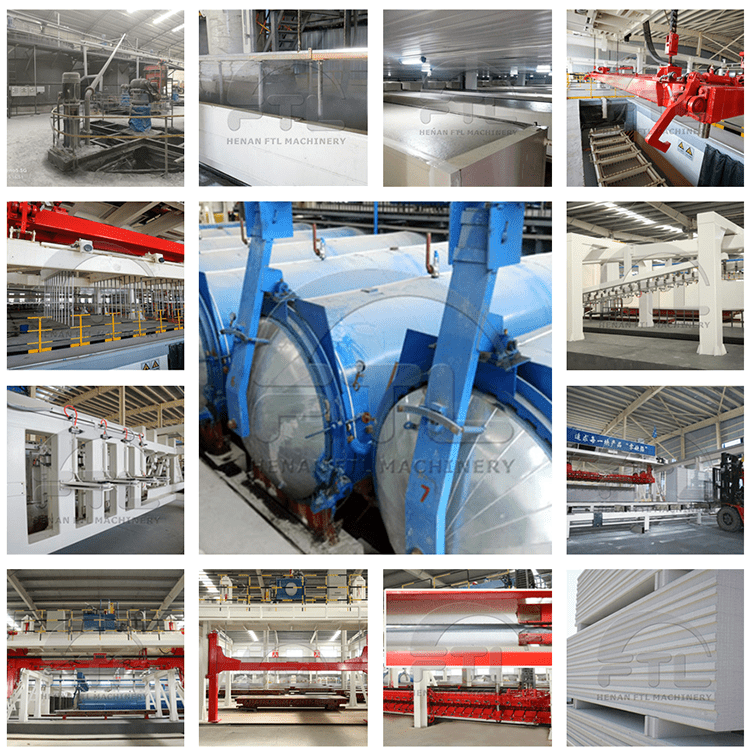

2. ALC panel making process

2.1 Raw material storage

Sand, cement, lime, gypsum, aluminum paste should be stored in suitable place separately. Cement can be stored in closed silo. Lime after grinding should be stored in lime silo. Aluminum or aluminum paste must be stored hermetically, and cannot be kept longer than 6 months.

2.2 Raw material processing

Convey sand or fly ash to the ball mill (wet type) via the conveyor belt. After milling, the slurry will be pumped into the slurry storage tank by slurry pump.

2.3 Preparation and antiseptic treatment of reinforcement cage

A.The crimped rebar is straightened and stretched to the desired diameter, then cut to different lengths.

B. Use a steel mesh welding machine to weld into mesh sheets according to the arrangement of different lengths.

C.Two welded mesh, using H-membrane, and then welded into a cage.

D.Cages need to be embalmed and dried before they are used in the production process.

E. After pouring, the crane places the cage into the mold.

2.4 Batching, Mixing, Pouring

Lime and cement are transported by screw conveyor to dry powder weighing scale. The slurry is transported by the slurry pump to the slurry weighing scale. The powder and slurry are then mixed together in a pouring tank and after 5-6 minutes they are poured into the mould

2.5 Curing &cutting

The slurry in the mould stays in the curing room for 2-3hours. The temperature in the curing room should be kept at 50-70℃. After 2-3 hours, the slurry will harden and become lumpy, but cake-like, hard and soft. First, the cake is pulled out of the curing room together with the mould, and the steel cage crane pulls the drill rod out of the cake. The cake will then be rotated 90 degrees in the air by a reverse crane and placed on the cutting cart. The cutting trolley will move to the position of the cutting machine to complete side cutting, horizontal cutting and vertical cutting.

2.6 Autoclave

Cut the cake (green body) and put it on the steam car. There are two cakes on one steam car. Drag six or seven steam cars into the autoclave and stay for 10 to 12 hours

2.7 Finished product dealing

After 10 to 12 hours, the blocks will be pulled out of the autoclave by hoister. The finished blocks can be separated manually or mechanically. If you choose mechanical, the process is as follows:

A transport crane lifts blocks with side pallets onto rollers that can be moved. The block will be moved to the position of the separator. The separator separates the blocks layer by layer. Finally, another crane transports the blocks to the packing location. The side pallet will return to the reversed crane position and a new mould will be assembled and used again.