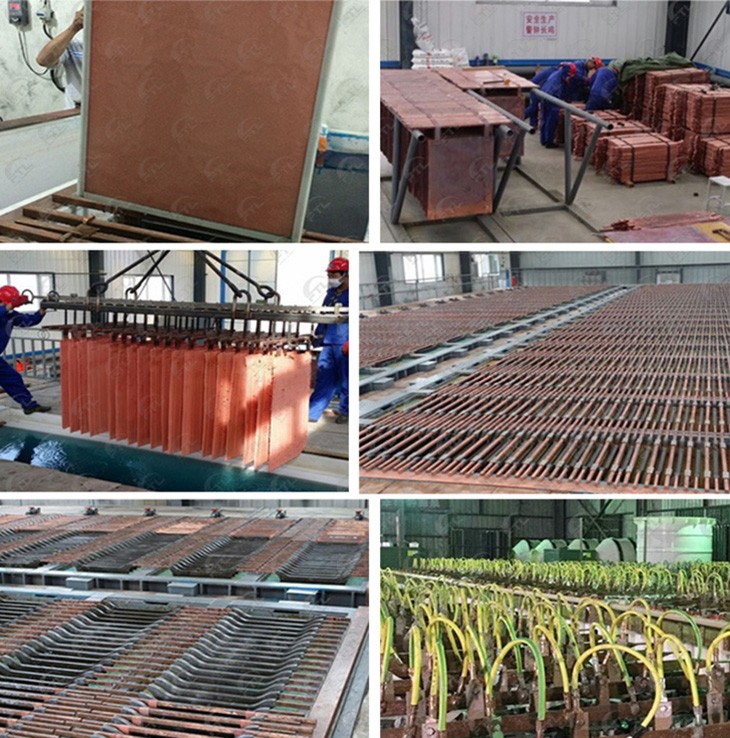

Copper Electrowinning Equipment

In the copper electrowinning process, the copper extraction methods are usually divided into two types: pyrometallurgy and hydrometallurgy, each with its own unique process and equipment. With the advancement of technology, both pyroelectrolysis and hydroelectrolysis equipment play a vital role in copper production, helping smelting plant to extract high-purity copper efficiently and environmentally friendly.

Copper ore pyroelectrolysis equipment

Copper ore pyroelectrolysis is a process that combines high-temperature smelting with electrolysis, which is widely used in copper ore processing and copper refining. Its basic principle is to heat copper ore to a high temperature through a smelting furnace to form Blister Copper and then obtain high-purity copper through electrolytic refining.

Pyroelectrolysis equipmen mainly includes smelting furnace, electrolytic cell, electrolyte system and power supply system.

Copper ore hydroelectrolysis equipment

Hydroelectrolysis adopts a combination of chemical dissolution and electrolytic refining, which is mainly used for the recovery and refining of copper ore, scrap copper and other copper-containing materials. Compared with pyrometallurgy, hydroelectrolysis has lower energy consumption and better environmental protection.

The main equipment of hydroelectrolysis includes leaching tank, solution purification and enrichment system, electrolytic cell, electrolyte circulation system, power supply system.

In the copper smelting process, the choice of pyroelectrolysis or hydroelectrolysis depends on many factors, including ore type, copper grade, production scale and environmental protection requirements. Pyroelectrolysis is suitable for the smelting of a large number of copper mines and can maintain a high copper extraction efficiency in large-scale production. Hydroelectrolysis is more suitable for waste copper recovery and low-grade ore processing, with lower energy consumption and better environmental protection performance.