CO₂ Recovery Plant

High efficiency · Energy saving · Environmental protection —— Your trusted CO₂ recovery solution

The CO₂ recovery equipment independently developed by our company is widely used in beer, beverage, fertilizer, fermentation, biopharmaceutical and other industries. The system can efficiently recover CO₂ gas from industrial tail gas, and obtain food grade or industrial grade liquid CO₂ after purification, compression, cooling, drying, deodorization, liquefaction and other multi-stage treatment.

Product features

Green and environmentally friendly: reduce carbon emissions and respond to the global "dual carbon" strategy.

High degree of automation: PLC automatic control, full process intelligent monitoring.

High purification efficiency: multi-stage filtration, impurities, odors and moisture are all removed.

High liquefaction rate: efficient condensation system, low energy consumption and high efficiency.

Compact structure and easy installation: modular design, short on-site installation cycle.

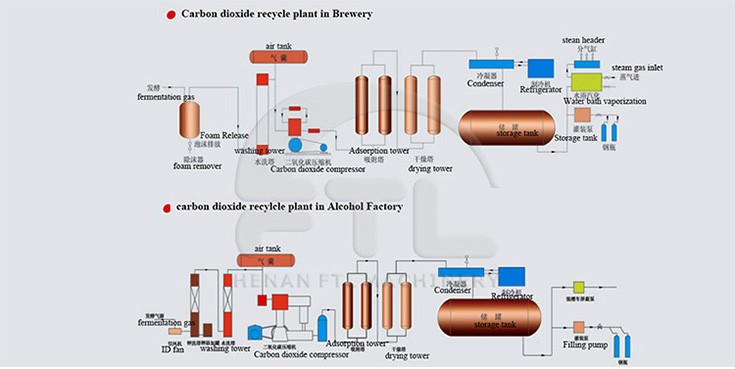

CO2 recovery process flow chart

Process flow overview: tail gas → filtration and dust removal → Scrubber → compression → adsorption and drying → refrigeration and cooling → condensation and liquefaction → liquid CO₂ storage tank

1. Tail gas (CO₂ source)

Source: tail gas from production lines such as fermentation, alcohol, fertilizer, methanol, flue gas, power plant, etc.;

2. Dust Filter

Function: Remove large dust particles and impurities from tail gas;

Principle: Use high-efficiency dust filter cartridges or primary filters to prevent particles from entering subsequent equipment and causing wear or blockage.

3. Scrubber / Washing Tower

Function:

• Remove water-soluble impurities (such as ammonia, alcohols, SO₂, etc.);

• Simultaneously perform preliminary cooling of the exhaust gas (cooling down by 10~20℃);

• Principle: The exhaust gas passes through the spray water layer from bottom to top, fully contacts with water, and impurities are absorbed or condensed.

4. Compressor (CO₂ Compressor) •

Function:

• Compress low-pressure CO₂ to the required working pressure (generally 0.8~1.2MPa);

• Helps in subsequent condensation and liquefaction;

• Features: Special oil-free CO₂ gas compressor.

5. Activated Carbon Adsorber

Function:

• Remove organic odors (alcohol, aldehydes, etc.) from the gas;

• Purify the gas and improve the purity of CO₂;

• Principle: Multi-stage activated carbon tanks or catalytic bed adsorbers, regularly replaced or regenerated.

6. Dryer

Function: • Remove moisture from the gas (dew point must be lower than -40℃);

• Type: Molecular sieve dryer;

• Principle: Prevent moisture from freezing in the condensation process, blocking the heat exchanger or affecting the purity of CO₂.

7. Fine Filter

Function:

• The last gas purification to ensure the removal of fine particles, oil mist and residual impurities;

• Protect the safe operation of the liquefaction system.

8. Refrigeration System

Function:

• Provide a stable low-temperature cold source to the entire liquefaction system (including the condenser);

• Cool down to the liquefaction temperature of CO₂ (-20℃ to -30℃);

• Usually a screw refrigeration unit + evaporator + refrigerant circulation system.

9. Liquefier / Condenser

Function:

• Liquefy high-purity CO₂ gas into liquid CO₂ at low temperature;

Principle: The gas contacts the cold surface of the heat exchanger, releases heat and condenses into liquid.

10.Liquid CO₂ Tank

• Function: • Store high-purity liquid CO₂ obtained after condensation;

The storage tank is a vacuum insulation type or a low-temperature pressure vessel, the temperature is maintained at -20~-30℃, and the pressure is about 2~3MPa;

• Purposes: Provide CO2 for food industry, welding shielding gas, dry ice manufacturing, beverage factory, etc.